Supply Chain in the Water and Beverage Industry: Requirements and Strategies for Efficient Production

The water and beverage industry is one of the most dynamic and demanding segments of the food sector, especially when it comes to supply chain management. Companies operating in this space face a unique set of challenges: maintaining consistent product quality, handling high-volume production, and optimizing global distribution networks.

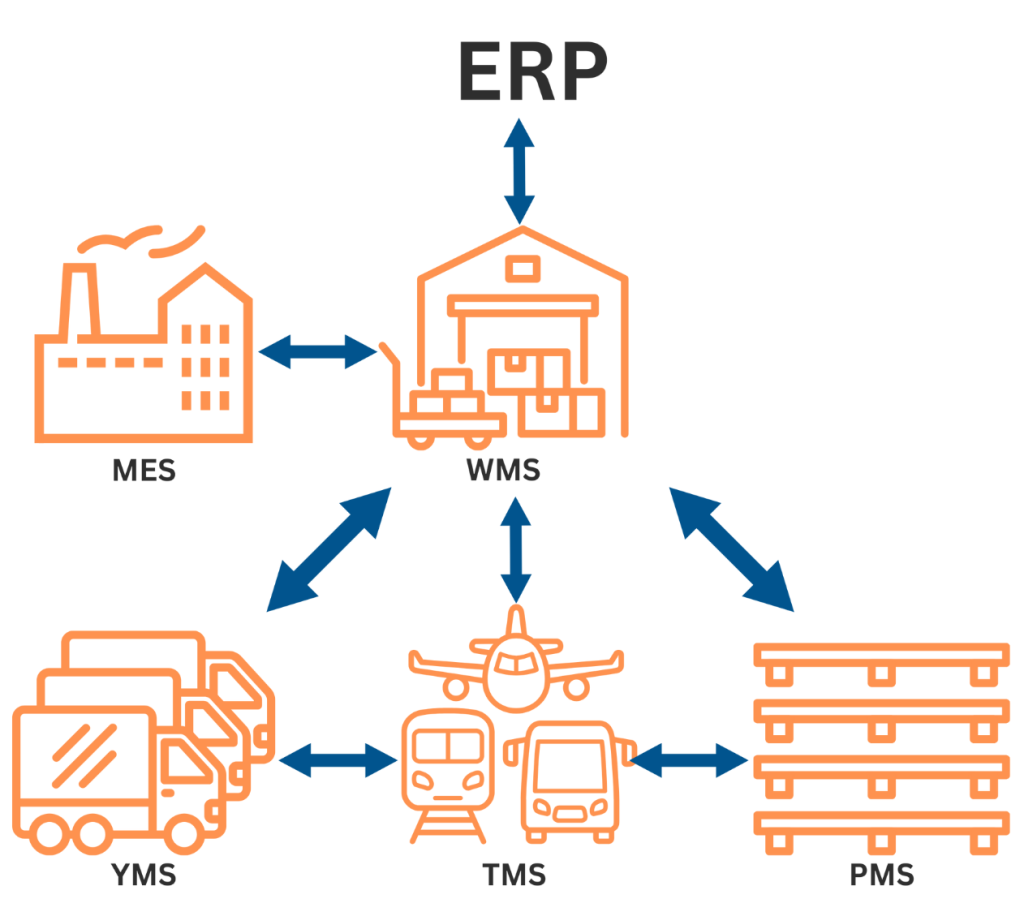

Through this article, we aim to share our experience in implementing complex traceability solutions within the food industry, with a particular focus on the beverage sector. The complexity of operational flows has often required the deployment of multiple applications from the xTrack suite by Axes Software.

- xTrack WMS for automating complex goods and quality flows – covering raw materials, packaging, and finished products.

- xTrack MES for planning, launching, and executing production while ensuring high-quality finished goods and real-time data collection for full traceability.

- xTrack YMS for planning truck movements within factory premises and enabling efficient distribution. The system also manages inbound access for raw material deliveries.

- xTrack PMS for managing all returnable packaging, ranging from pallets and crates to bottles and even beer kegs. Losing traceability on packaging leads to higher production costs due to replacement purchases, as well as increased environmental taxes.

- xTrack TMS for managing transport operations and optimizing delivery costs.

The beverage category includes:

- Bottled water (still and sparkling);

- Soft drinks and carbonated beverages;

- Alcoholic drinks (beer, wine, spirits).

The supply chain in the water and beverage industry operates at an immense scale, where profit margins are razor-thin. This reality demands an exceptional level of operational efficiency.

Companies must manage raw material sourcing, handle perishable ingredients, and maintain strict quality standards, all while navigating seasonal fluctuations in production and delivery volumes. These factors create a highly complex logistics ecosystem that can only operate efficiently with the support of technology solutions designed to meet every requirement, especially those related to traceability, which plays a key role in enhancing operational performance.

Before exploring how technology can address these challenges, let’s take a closer look at the specific characteristics and core requirements of the water and beverage production process.

Unique Operational Characteristics of the Water and Beverage Industry

The most critical aspect is traceability and quality assurance. In production, traceability means knowing everything about the goods you produce and deliver, ideally down to each individual bottle. When we talk about traceability, we must be able to answer the following questions:

- Who produced it – and we’re referring to every stage of the production flow

- When was it produced (date, hour, and minute)

- On which machine was it produced

- What raw materials were used, including the pallets they arrived on, the specific batches, and the quality parameters recorded for those materials

Beverage production involves managing massive volumes, with some factories reaching outputs of over 2,000 bottles per minute. The supply chain must be both flexible and robust enough to support a wide range of packaging formats, from small 235 ml cans to 2-liter bottles and large containers of 5 or even 19 liters. It also needs to accommodate multiple product recipes and extensive distribution networks that serve everything from neighborhood shops to major retail chains.

Shelf-life management is essential, especially for soft drinks, where flavor can degrade over time. While water-based products are generally more stable, they still require rigorous monitoring to prevent any form of contamination throughout the supply chain. Both soft drinks and bottled water demand flawless coordination between production planning, inventory management, and distribution to maintain product freshness and minimize waste.

Sales in the beverage industry are heavily influenced by impulsive consumer behavior, often driven by seasonality – such as the summer months – or by specific events. In this context, the supply chain must be highly agile, capable of responding quickly to sudden demand fluctuations and ensuring product availability precisely when and where it’s needed.

Although the recipes may seem simple at first glance, the quality of core ingredients, such as water, sugar, and flavorings, is crucial to the success of the final product. Even a slight variation in water composition can alter the taste, impacting consumer perception and, ultimately, brand reputation. That’s why water treatment and strict quality control of every ingredient are critical processes in beverage production.

Contamination risks are high, especially for non-carbonated and non-alcoholic beverages, where the production environment is more vulnerable to microbiological threats. That’s why hygiene and sanitation standards are exceptionally strict, and cleaning and disinfection processes must be continuously monitored to ensure the safety of the final product.

Packaging and sustainability have become strategic priorities in the water and soft drink industry, driven by increasing pressure to reduce waste. Manufacturers are no longer responsible solely for the production process, they must now manage the entire lifecycle of packaging. Material optimization, bottle and can collection, and recycling have become essential components of operational planning and key drivers in building a responsible brand image.

Modern Requirements for Operational Efficiency

Water and quality management are foundational pillars in the supply chain strategy for bottled water companies. Water is treated, or more precisely, filtered, to remove impurities and elements that could affect long-term stability, such as iron oxides or other minerals. The quality of the water or beverage is measured after packaging at regular intervals, and the results are recorded in the quality management system. The xTrack application suite provides a flexible module for logging quality parameters. Obtaining these parameters takes time, typically around 48 hours, during which the goods cannot be shipped, as they remain in quarantine.

Ingredient sourcing requires careful planning, especially for natural components like fruits and aromatic plants, whose availability is often seasonal. To avoid production bottlenecks, companies must adopt flexible procurement strategies. The shelf life of these sensitive raw materials varies depending on storage conditions. In addition, packaging materials, bottles, cans, labels, and caps, must be perfectly synchronized with production rhythms to arrive just-in-time, minimizing storage costs and preventing delays in the manufacturing chain.

Material stock levels can become misaligned when based on theoretical consumption rather than actual usage. Without a system to track real consumption, discrepancies between recorded and real inventory can lead to two outcomes:

- Overstocking – when recipes are defined as “covering” or overly generous. This leads to financial immobilization through excess inventory.

- Stock shortages – when recipes are defined with minimal consumption estimates. This can lead to situations where production cannot meet demand, resulting in lost sales and, ultimately, financial losses.

Concentrate and syrup management plays a vital role in soft drink production. From our perspective, obtaining these components is just one stage in a broader production chain. In some cases, concentrates are produced in separate facilities; in others, they’re made directly within the packaging flow. From a traceability standpoint, the first approach is simpler, but it introduces supply chain challenges related to transportation and timely delivery. In-line concentrate production, within the same facility, presents its own traceability complexities. For example, a single syrup batch may be used across multiple production orders – both for 0.5L and 2L packaging. The key traceability question becomes: “Which specific bag of sugar was used to produce the beverage bottled in 2L format?”

Production and packaging in the water and soft drink industry run at remarkable speeds, with some bottling lines reaching over 100,000 bottles per hour. This accelerated pace demands meticulous coordination across packaging formats, rapid product changeovers, and minimal downtime for cleaning and maintenance. Factories must efficiently manage glass bottles, PET containers, aluminum cans, and a wide range of caps, while maintaining smooth production flow and strict quality standards.

From a logistics perspective, the challenge is ensuring that all materials are available at the line precisely when needed, while avoiding costly errors, such as loading red caps for a product that requires green ones.

Quality control is a core element in beverage production, where hygiene standards are exceptionally strict and processes must be precisely monitored. Quality applies to raw materials and packaging, to semi-finished products, and especially to finished goods. Each of these categories is tracked using distinct quality parameters. If these parameters are not measured, or if the values fall outside the accepted range, the goods from the corresponding pallet or batch must not be consumed or shipped.

Quality control systems monitor a wide range of parameters – from ingredient composition and processing temperature to carbonation levels (in the case of carbonated beverages) and microbiological safety. In addition, traceability and batch tracking systems are essential for regulatory compliance and for enabling rapid intervention when quality issues arise.

Cold Chain and Distribution

Many products in the beverage industry require storage and transport under controlled temperature conditions to preserve quality and extend shelf life. Cold chain management involves careful coordination of refrigerated storage facilities, temperature-regulated transport, and proper handling throughout the entire distribution network.

Route optimization, load consolidation, and precise delivery scheduling significantly contribute to profitability, while ensuring that products reach points of sale under ideal conditions.

To maximize delivery efficiency, truck loading times at the finished goods warehouse must be kept to a minimum. For this, goods that are not shipped as full pallets need to be prepared in advance, and pallet arrangement must follow client-specific rules.

At this stage of the beverage supply chain, WMS (Warehouse Management Systems), TMS (Transport Management Systems), and route optimization tools are essential, especially for last-mile delivery. High delivery volumes also require structured coordination of incoming trucks for loading and distribution. In this context, a Yard Management System (YMS) becomes valuable for controlling truck access to the yard, scheduling loading operations, and issuing the necessary documentation.

Digitalization and Software Integration Strategies

Producers of bottled water and soft drinks rely on advanced software systems to manage the complexity of high-volume operations – from production to distribution. These digital solutions are essential for maintaining tight profit margins and boosting operational efficiency. They provide real-time visibility, automate repetitive tasks, and support informed decision-making based on concrete data.

xTrack MES Production Execution Systems in Beverage Plants

Manufacturing Execution Systems (MES) play a key role in bridging ERP (Enterprise Resource Planning) platforms with real-time production activities. In the beverage industry, MES solutions track production speed, quality parameters, and equipment performance, ensuring high levels of operational efficiency.

xtrack MES from Axes Software

xTrack MES is a specialized solution designed to meet the unique challenges of the food and beverage industry. The platform offers a comprehensive range of functionalities, perfectly aligned with the sector’s strict requirements for quality, safety, and operational efficiency.

Funcționalities

Detailed production planning starts with the sales forecast for each item. Forecasts are typically created monthly and broken down by week. Once production needs are established based on these forecasts, weekly production plans can be developed, further divided by day and by production line. xTrack MES generates these plans while factoring in the availability of raw materials and packaging supplies.

Through its supply planning module, xTrack applications can generate purchase orders from suppliers based on sales forecasts, existing production plans that will consume raw materials, and current inventory levels. Planning also takes into account supplier lead times.

Sales forecasting itself involves a wide range of parameters – some known and handled by deterministic algorithms, others inferred by AI agents. For example, a rise in average temperatures compared to the previous year may signal increased demand, while a rainier season could lead to lower sales volumes.

Real-Time Traceability: xTrack MES provides complete visibility for every product – from raw materials to finished goods. The system enables batch and serial tracking at the pallet level (SSCC – Serial Shipping Container Code), recording every operation performed, every component used, and every quality check conducted. This level of transparency is essential for both efficient product recalls and compliance with regulatory standards.

In practice, traceability is achieved by declaring the type of pallet or barrel brought to the line, the exact moment the production line is fed with that item, and the quantity consumed.

Through a simple data entry operation on a tablet, precise consumption data is collected: “who?”, “when?”, “which equipment?”, “what quantity?”, “which batch?” – while automatically validating the accuracy of the operation. This ensures that the production line is not fed with incorrect items or batches.

Production declaration is converted into a pallet label printout, featuring a unique SSCC (Serial Shipping Container Code) for system-wide identification. The pallet is then transferred to the warehouse either by automated systems or a forklift. Through a fully automated process, the system captures key data points: when, how much, which batch, which equipment, and who, covering both finished and semi-finished products, as applicable.

Repackaging is a critical aspect of the beverage industry. Some clients request shelf-ready boxes containing a mix of finished products, for example, a box with 2 bottles of orange juice, 2 of lemon juice, and 2 of apple juice. These components typically come from separate production orders and carry different batch numbers. The mixing process itself constitutes a new production order, generating a new batch that must maintain full traceability: which original batches were used, who performed the mixing, and when the operation took place.

These xTrack MES functionalities ensure compliance with both European and U.S. regulations, supporting full adherence to the “farm to fork” principle.

Inventory and Material Management: xTrack MES, together with the xTrack WMS application, monitors in real time the flow of raw materials, work-in-progress (WIP), and finished goods within the factory. The system ensures that the right materials are available exactly when and where they’re needed, significantly reducing downtime caused by shortages.

It all begins with procurement and the receipt of goods into the raw materials warehouse. xTrack WMS guides operators to store items according to each product’s specific requirements, such as temperature conditions. Quality control of raw materials and packaging is an integral part of this management flow. Production orders generated according to the planning schedule trigger supply tasks for the production lines, as well as the release of unused materials left over from previous orders. In the WIP area, consumption is declared at the moment it occurs, maintaining a clear and accurate record of stock levels.

In the beverage industry, finished products are bottled on automated lines. Using a GS1 pallet labeling system simplifies production declaration. Each label is automatically scanned on the line, and the produced quantity is recorded at pallet level. Once the finished product enters xTrack WMS inventory, the system also generates a handover note (NP) or a goods receipt (NIR) message for the ERP application.

However, the goods are not immediately available for delivery, as quality data must first be entered. Final delivery is managed by the xTrack WMS application, based on customer orders received from the ERP system.

Finally, we turn to the management of semi-finished products, which in the beverage industry typically exist in flow, stored in tanks. Naturally, these intermediate stocks must be tracked to allow for accurate consumption declarations. The process becomes fully automated through data capture from weighing systems and PLCs that control the equipment. Semi-finished products are essential for completing the traceability of the finished product. In other industries, these intermediates may be managed at the pallet or barrel level, each uniquely identified in the system by batch.

Recipe Management: xTrack MES helps ensure consistent product quality through precise recipe control. The system enforces exact ingredient dosing and strict mixing sequences, minimizing human error and ensuring compliance with the technical specifications of the final product.

Some ingredients, such as sugar, require particularly strict control due to their constant concentration requirements. While different suppliers may provide varying sweetness levels, the syrup base for a juice must meet a specific sugar concentration. As a result, actual consumption may differ from the theoretical recipe. One of the key advantages of xTrack MES is its ability to capture the exact quantities consumed. This also enables accurate cost calculation for each production batch, based on the real recipe used.

Another important aspect to consider is the ability to substitute items within a recipe. A practical example is the bottle cap, which may be available in multiple variants. If the specific cap listed in the recipe is not in stock, a similar, often higher-quality, alternative can be used. While this substitution may alter the final product’s cost of production, the benefit lies in avoiding stockouts and ensuring that sales targets are met according to forecast.

The scripted production recipe doesn’t always reflect reality. It includes assumed losses that occur when starting up the line for a new production order, losses accepted as part of equipment calibration. In practice, the percentage of waste relative to total output may vary depending on production volume. The more you produce, the lower the percentage of loss, and actual consumption tends to be lower. This variation can impact inventory levels and lead to inaccurate production cost records. xTrack MES helps capture real consumption data and adjust production recipes accordingly.

Allergen Control and Food Safety: The system integrates advanced functionalities to prevent cross-contamination and ensure food safety. It can manage allergen matrices, rigorously monitor cleaning and sanitation procedures, and enforce strict production sequences to separate products containing different allergens. These measures are essential for protecting consumers and complying with current regulations.

Importantly, all time required for cleaning and sanitizing production lines is factored into production planning.

Real-Time Quality Control: xTrack MES connects directly with laboratory equipment and quality control systems, automatically collecting and analyzing relevant data. The system can monitor critical parameters in real time, such as temperature, pH, viscosity, and carbonation level, instantly alerting operators to any deviations and enabling rapid corrective actions to maintain quality standards.

Quality and its traceability are highly complex under current EU and U.S. regulations. Traceability must follow the principle of prevention, which can only be achieved by measuring all quality parameters at every stage of production, from raw materials to finished goods, and throughout the distribution process. Within the factory, we’ve implemented multiple stages of a structured quality process.

- Raw Material and Packaging Quality Control: For each item in these categories, specific quality parameters are defined, measured in the factory’s own laboratories, and compared against the supplier’s declared values. At the batch level, the system records accepted thresholds, measured values, and supplier-declared specifications for every parameter. Each item may require multiple quality checks. To ensure full batch-level traceability, copies of quality documents issued by the producer and/or supplier are also stored. Given that we’re dealing with food products, all materials that come into contact with the product, including cardboard boxes and packaging films, must undergo quality verification. Only items that pass these checks are approved for use in the production flow.

- Finished products have distinct quality parameters that must be measured – following the same principles applied to raw materials. While quality documents are not stored at this stage, they are issued at the time of delivery. To assess quality values, samples are taken from production lines at regular intervals, and data is saved for the pallets produced during that timeframe so that the measured parameters can be applied accordingly. Quality measurement can take up to 24 hours, during which time the finished product pallets cannot be shipped. The quality department performs these checks periodically, and once the parameter values are confirmed, they are entered into the system. The corresponding batch or pallet group is then released or removed from quarantine for delivery. A key advantage of xTrack WMS is its ability to block pallets from being shipped regardless of their storage location. This means quarantine doesn’t require a separate warehouse zone, eliminating unnecessary pallet movements within the finished goods warehouse.

- In-Process Quality Control: Quality is measured and recorded in product-level quality reports. In certain implementations, we’ve gone a step further, ensuring documented proof that a quality team member has periodically visited the production line, collected samples, and inspected the process itself. These inspections are logged in the application, capturing the identity of the person, the time, the production line (equipment), and the finished product being inspected. The event is recorded in the database through a simple action on a tablet or handheld terminal.

With the quality module from Axes Software and the full traceability provided by the xTrack suite, our clients can meet even the most demanding end-customer requirements – often verified through regular audit activities.

Requests like “Tell me everything about this bottle… within the hour” are answered in under a minute, thanks to automatically generated traceability reports. Of course, the auditor must also specify which pallet the bottle came from 😊.

Integrating xTrack MES with a Laboratory Information Management System (LIMS) transforms quality control from a reactive process into a proactive one. This direct connection enables real-time transmission of lab data to the production system, eliminating human error and ensuring full traceability.

The system continuously monitors quality parameters, and if a lab result exceeds predefined thresholds, xTrack MES can instantly trigger an alert or automatically stop the production line. This prevents the manufacturing of non-compliant products and ensures that every batch meets the highest safety and quality standards.

Performance Analysis (OEE): xTrack MES plays a strategic role in calculating Overall Equipment Effectiveness (OEE) – a key indicator that reflects the true productivity of the production process. OEE is determined by multiplying availability, performance, and quality. Our system provides real-time data for each component, enabling rapid identification of bottlenecks and continuous optimization of operational efficiency.

For more details on how OEE is calculated, read our dedicated blog article here.

Warehouse Management with xTrack WMS by Axes Software

In a sector where every second counts, WMS solutions turn logistical challenges into opportunities. For beverage manufacturers, this means better-organized warehouses, faster operations, and lower costs.

xTrack WMS meets the precise demands of the food and beverage industry, offering an agile, flexible, and scalable platform for efficient warehouse management. With functionalities tailored to the fast-paced nature of this sector, xTrack WMS streamlines processes and supports operational performance.

Functionalities:

xTrack WMS revolutionizes inbound logistics by fully automating the receiving process. Upon delivery, the system scans products using barcodes and instantly verifies them against purchase orders. It then guides operators to move pallets to the most efficient storage locations, taking into account product type, temperature requirements, and current stock levels. The result: fast, accurate, and error-free operations.

xTrack WMS takes inventory management in the beverage industry to the next level. Beyond basic tracking, the system implements advanced rules such as:

- FEFO (First Expired, First Out): This principle is often more critical than FIFO when dealing with perishable goods such as juice, milk, or beer. In fact, every item that comes into contact with food must be tracked by batch. If an expiration date is not available, the system relies on the production date and applies the FPFO (First Produced, First Out) principle instead. xTrack WMS automatically prioritizes items with the nearest expiration dates, or the oldest production dates, helping reduce waste and ensure product freshness.

- Lot Control: Each product is precisely tracked by its batch number, ensuring full traceability and compliance with food safety regulations. In the event of a recall, the system instantly identifies the location of every affected item. xTrack systems go even further, down to pallet-level traceability using SSCC (Serial Shipping Container Code), generated according to GS1 standards. For each pallet, the system records the raw material batches, production time, equipment used, personnel involved, and many other data points, enabling complete lot-level traceability.

- Real-Time Inventory Visibility: Managers gain a complete, up-to-date view of inventory, from receiving to dispatch, helping prevent stockouts and overstocking. Real-time means a pallet of finished goods appears in stock the moment it’s labeled or wrapped on the production line. To avoid overloading the ERP system with accounting entries for small quantities, stock updates are sent with a delay. Similarly, raw material consumption is recorded at the moment of actual use, and the ERP is updated later, often at the close of the production order, to avoid excessive data traffic from consumption notes.

- The result? A smarter, safer, and more efficient supply chain

Benefits for Manufacturers and Distributors

xTrack WMS streamlines outbound logistics and order fulfillment through intelligent orchestration of picking, packing, and shipping processes. With optimized picking routes and direct connectivity to carriers, the system reduces processing time, minimizes errors, and ensures fast, accurate deliveries. In scenarios involving partial pallet shipments, the picking and pallet composition activities must be separated from full pallet picking and completed in advance of truck arrival. Pallet arrangement must follow configurable client-specific rules and consider product attributes such as fragility, dimensions, and weight.

xTrack WMS intelligently optimizes warehouse space by placing fast-moving items in easily accessible zones and slower-moving goods in less trafficked areas. The result? Maximum use of every square meter and a smooth operational flow that reduces handling time and boosts productivity. Another example of space optimization is the strategic use of Drive-In racks. When a production order is launched, the system selects the optimal Drive-In rack based on the quantity to be produced, or more precisely, the number of pallets expected.

xTrack WMS integrates seamlessly with ERP, MES, and TMS systems, creating a continuous flow of information—from raw material intake to final product delivery. This end-to-end integration ensures full traceability, complete supply chain visibility, and smooth, uninterrupted operations.

AQUA CARPATICA CASE STUDY

AQUA Carpatica chose xTrack WMS, our warehouse management solution, to optimize operations and deliver products of the highest quality to its customers. By digitizing its processes, the company significantly improved efficiency and reduced operational costs.

All automation in this project was implemented using Zebra Technologies devices, ensuring enhanced traceability throughout the entire production flow.

Discover AQUA Carpatica’s transformation strategy and the results achieved in the video below!

xTrack TMS by Axes Software and Beverage Logistics

For beverage producers, distribution isn’t just about delivery—it’s about speed, volume, and precision. TMS solutions turn logistics into a competitive advantage, with optimized routes, reduced costs, and flawless deliveries to every point of sale.

Our platform meets the real-world needs of food and beverage manufacturers. With an intuitive and scalable solution, we manage distribution logistics efficiently—cutting costs and accelerating delivery speed.

Functionalities:

Route and load optimization becomes effortless with our intelligent system. It analyzes delivery locations, vehicle capacity, traffic conditions, and time windows to generate efficient routes. Small orders are consolidated into full shipments, and LTL deliveries are optimized to minimize empty miles and save fuel, ensuring faster, more cost-effective distribution.

xTrack TMS provides full control over transport costs. With features like automated invoice auditing, precise cost allocation per order, and future scenario simulations, the system helps identify savings opportunities and negotiate better rates with carriers. Any additional cost must be entered into the application to ensure full traceability of transport service billing.

xTrack TMS also offers complete real-time fleet visibility through GPS and telematics integration. Managers can track every vehicle, anticipate delays, and communicate proactively with customers. Live data enables driver performance evaluation and ensures strict adherence to delivery schedules, all contributing to faster, safer, and more transparent distribution.

xTrack TMS integrates seamlessly with WMS and ERP modules, enabling real-time data flow between warehouse and distribution. Orders ready for dispatch are automatically retrieved, allowing fast and accurate route planning. This integration eliminates information bottlenecks and ensures smooth, efficient, and error-free deliveries.

When multiple xTrack applications are used, we recommend a single integration point with external systems, typically the ERP, handled through the WMS module. Transport planning in TMS primarily supports WMS for preparing goods and YMS for scheduling truck loading. From TMS to ERP, only vehicle data should be transferred for inclusion in delivery documents. These vehicle details are also known by WMS, which sends them immediately after loading is completed.

xTrack YMS for Beverage Plants and Distribution Centers

xTrack YMS ensures efficient coordination of activities in the yard area surrounding the warehouse. In practice, YMS acts as the bridge between WMS and TMS applications.

All trucks scheduled through the TMS must be assigned a loading slot and dock. The loading date and time are planned based on the final customer’s requirements, including delivery deadlines and receiving hours.

xTrack YMS Manages the Following Yard Operations

➡️ Truck departure confirmation – Verifies when a vehicle exits the warehouse premises

➡️ Loading/unloading scheduling – Plans dock activities based on transport assignments and warehouse readiness

➡️ Arrival validation – Confirms truck arrival using multiple methods (e.g., gate check-in, license plate recognition)

➡️ Driver communication – Interaction through various channels; most actions are validated via WMS data (e.g., start of loading/unloading)

➡️ Yard entry approval for loading – Access granted based on transport plans and dock availability

➡️ Loading start confirmation (via WMS) – Multiple docks can be scheduled depending on product availability

➡️ Loading completion confirmation – Marks the end of the loading process

➡️ Final departure confirmation – Confirms the truck has left the yard after loading is complete

xTrack PMS for Food Industry Operations

Packaging traceability is a critical aspect of production, especially in the beverage industry, where packaging materials – particularly pallets – can represent a significant cost. These items hold substantial value on the black market for pallets and recycling, making their tracking essential.

For our clients, implementing the xTrack PMS application was a straightforward decision, as it complements other modules in the suite. Certain process stages are automated by WMS or MES, simplifying pallet traceability and reducing manual effort.

Unlike other industries, beverage production involves large volumes of packaging for each product type, especially pallets. The status of each pallet can be defined flexibly, depending on operational needs.

What do users of our applications want to know about packaging:

- How many packaging units are available in the factory for use in production

- How many packaging units are currently loaded with goods and stored in the warehouse

- How many packaging units are at the customer’s location

- How many packaging units are damaged and require repair or refurbishment

- What are the packaging losses over a given period

- How many packaging units are currently managed by drivers

Packaging status transitions are typically triggered by events executed in WMS or MES. For example, when a pallet is packed, its status changes from “empty” to “loaded.” The same applies during truck loading, where the pallet’s state is updated accordingly.

Once the full process flow is completed, the system automatically generates all required documents: pallet delivery notes, goods receipt records (NIR), pallet invoices, and disposal reports.

xTrack PMS also supports client-side packaging inventory management by tracking return deadlines. These deadlines, often set by large retail chains, indicate when packaging must be collected. Monitoring these timelines helps optimize the recovery process, factoring in truck capacity and route planning.

In the beverage industry, packaging includes high-value items like KEGs (beer barrels). Due to their acquisition cost, KEGs are tracked individually using serial numbers, either printed as barcodes or embedded as RFID tags for fast identification at check-in and check-out.

Serializing packaging units allows for tracking the number of uses per item, an essential feature for calculating production costs by factoring in indirect usage costs, especially for high-value assets like KEGs. This usage-based accounting helps manufacturers better understand the lifecycle value of each unit.

For non-serialized packaging, such as pallets, usage is calculated at batch or period level, for example, by comparing the number of pallets delivered versus those purchased.

Packaging management can also be handled independently, without exchanging data with the ERP system, depending on the client’s preferences. This flexibility allows businesses to tailor their traceability and cost-tracking processes to operational realities.

Technological trends shaping the future of this complex field

Artificial Intelligence (AI) and Machine Learning (ML)

AI and ML technologies enable intelligent supply chain management in the beverage industry. Through advanced algorithms, systems can forecast demand, prevent equipment failures via predictive maintenance, and optimize distribution based on real-world conditions. These capabilities automate critical processes and provide a solid foundation for real-time strategic decision-making.

Internet of Things (IoT) and Sensor Technology IoT sensors embedded throughout the supply chain offer extended operational visibility. Smart packaging ensures continuous monitoring of temperature and freshness, while industrial sensors enable predictive maintenance and real-time quality control. These features enhance reliability, traceability, and compliance in food and beverage distribution.

Blockchain Technology Blockchain ensures end-to-end traceability across the supply chain, allowing every ingredient to be tracked from producer to point of sale. This heightened transparency supports rapid intervention in case of non-compliance and reinforces adherence to food safety regulations.

Automation and Robotics From automated picking to robotic palletizing, automation technologies streamline logistics operations, reduce costs, and improve accuracy. On the production side, automated lines increase throughput, reduce quality variability, and lower reliance on manual labor.

The beverage industry demands specialized logistics strategies built on sophisticated supply chain management. As consumer preferences evolve and competition intensifies, companies must invest in advanced capabilities, from forecasting and traceability to distribution optimization. Implementing comprehensive strategies ensures operational resilience, consistent quality, and long-term financial performance.

What lies between top-tier production and a flawless consumer experience? A supply chain that runs seamlessly. In the beverage industry, every milliliter matters. Success depends on agility, precision, and control.

ERP Systems (Enterprise Resource Planning)

In the early days, manufacturing companies relied on MRP (Material Requirements Planning) systems, introduced in the 1960s and 1970s, to plan material needs. These applications focused on calculating raw material quantities and scheduling orders, aiming to reduce inventory levels and avoid delays.

By the 1980s, systems evolved into MRP II (Manufacturing Resource Planning), expanding beyond materials to include production resources such as equipment, capacity, and personnel. Planning became more complex and better aligned with real factory conditions.

In the 1990s, companies began seeking broader process integration. This led to the emergence of ERP (Enterprise Resource Planning) systems, which unified all core functions, production, logistics, sales, finance, and HR, into a single platform. Unlike MRP/MRP II, ERP systems offer a comprehensive view of the entire organization, enabling real-time coordination and data analysis.

Today, ERP systems serve as the command center for supply chain management in the beverage industry, integrating all business processes, from procurement and production to sales. For manufacturers, these systems must handle the complexity of recipes, including multi-ingredient formulations and variants, while ensuring full batch traceability throughout the production cycle in compliance with regulations and quality standards.

However, due to financial and accounting constraints within ERP platforms, the flexibility to configure these complex processes may be limited.

The xTrack application suite from Axes Software is designed to successfully handle any operational requirement related to production workflows. Based on our experience across numerous implementation projects, we know that many operational processes cannot be fully executed within a standard ERP system.

One example is recording actual consumption. While ERP systems can register these values, collecting real-time data from continuous production flows is costly and prone to errors. As a result, companies often rely on theoretical recipe-based consumption instead.

Another example: if only one pallet from a batch shows quality issues, the quantity on that pallet must be transferred to a quarantine inventory in the ERP to prevent delivery. However, if this process isn’t physically enforced, there’s a risk that the pallet may still be used in production or shipped to the customer.

In xTrack WMS, this risk is eliminated: the user simply cannot scan the SSCC of that pallet for such operations. And this is just one of many examples.

Improving production efficiency comes from extending ERP functionality through the use of the xTrack suite, bringing precision, control, and operational clarity to every step of the process.

Conclusions

All the concepts presented in this article apply equally to other areas of the food industry. For example, the production of sauces, jams, and canned goods shares the same operational requirements, especially when products are packaged in containers similar to those used in the beverage sector. In fact, these principles are relevant across the entire food manufacturing landscape.

With the Axes Software solutions, your supply chain becomes a smart network – not an obstacle course. Streamline your processes, gain full visibility, and control every step with precision.

👉 Request a personalized offer by filling out the form below.